Envelope Study.1

This initial envelope study uses an aerogel composite as a glazing solution. The aerogel would integrate into the façade at various apertures utilizing it's translucent property to provide partial transmission of light and simultaneously help control the thermal environment of the building.

A.V.3

This slow-motion video demonstrates what happens when a piece of polymethyl methacrylate (PMMA) made with aerogels is hit by a high-momentum projectile (the momentum is eight times higher than that of a .45-caliber bullet). This video is Nicholas Leventis, professor of chemistry at the University of Missouri-Rolla (Missouri University of Science and Technology) and is used to compare the strength of aerogels to conventional armor-grade PMMA. (see related video, "Shattered!"). Video courtesy of Hongbing Lu, professor of mechanical and aerospace engineering, at Oklahoma State University.

History of Aerogel

The first aerogels were produced in the late 1920s by Samuel Kistler, an undergraduate instructor at the College of the Pacific in Stockton, California. There is conflicting information regarding the precise timing of, and his motivation for, producing them, but throughout the twenties Kistler had been working with supercritical fluids (high-pressure fluids on the point of boiling). Whether by design or by accident, Kistler found a way to remove the fluid from a wet silica gel, leaving behind its solid structure. In the early 1930s, Kistler continued his experiments with aerogels, studying some of their thermal and catalytic properties.

The first commercial aerogels were produced in 1942 by the Mosanto corporation, under the trade name Santocel. The process involved soaking a sodium silicate solution in sulfuric acid, then repeatedly washing it in alcohol before drying it at high pressure. Mosanto described the product as "a light, friable, slightly opalescent solid containing as much as 95 percent air volume. It is a very effective heat insulating material." Mosanto claimed to have produced aerogels with densities of 1.8 pounds per cubic foot (29 kg/m3), but their regular output was between three and five pounds per cubic foot (48 to 80 kg/m3).

Mosanto marketed Santocel mainly as a flatting agent for paints and varnishes. Its applications, though not numerous, were as varied as thermal insulation in household freezers and an ingredient in Napalm. Because of its high manufacturing cost, however, Mosanto discontinued aerogel production in 1970.

nterest in aerogels, and their very low thermal conductivity, increased in the 1980s as energy conservation became increasingly important. However, high production costs still prevent their widespread use.

Aerogel FAQ'S

How is aerogel made?

Mixing four chemicals, which react to form a wet gel, similar to a gelatin dessert creates Aerogel. The gel is then dried in an autoclave, in essence a pressure cooker that applies pressure and heat.

What is it used for?

The Stardust Project is using aerogel as a capture media, where it will collect very small interstellar and cometary particles as they embed themselves in the porous aerogel. Because of its unique physical properties, aerogel has also been proposed for a wide variety of uses, including thermal insulation, acoustical insulation, optical components, catalytic supports and filters.

What does it feel like?

The microstructure of aerogel is extremely porous, so it feels like volcanic glass pumice or even a very fine, dry sponge, except that it is much lighter.

Why is it blue?

Aerogel has a blue cast for the same reason that the sky is blue. The very small particles that compose the aerogel scatter blue light, the same as our atmosphere scatters blue light. Similarly, when you look through the aerogel the light appears yellowish or reddish, like that of a sunrise or sunset.

Where can I get some aerogel?

Aerogel is commercially available in limited quantities from a few companies. These can be found quite easily by searching the Internet using the keyword: aerogel. JPL only produces specialized aerogel used for spaceflight.

How much does aerogel cost?

Aerogel is relatively expensive primarily because it is currently made in very limited quantities. While increasing the scale of aerogel production will reduce the cost, the basic process and raw materials are still somewhat costly. For relatively small quantities of aerogel the cost is about $1.00 per cubic centimeter for one liter.

What makes aerogel so special?

The fact that typical aerogels are between 95 and 99.5 percent porous gives them their unusual characteristics. Because of this highly porous quality they are characterized by extremely high surface area, high thermal and acoustical resistivity, low dielectric constant, and low refractive index. There are other materials that exhibit each of these properties, however, only aerogel exhibits all of these properties at the same time.

Who invented aerogel?

Aerogel was first made in the 1930s by Samuel S. Kistler, who obtained several patents for making a variety of aerogel, including silica, alumina, chromia, tin and carbon.

Why is it called a gel?

During the production of aerogel a wet gel is formed which when dried becomes filled with air. Thus the name aerogel, which means: air gel.

Is it solid?

Aerogel is made up of microscopic beads or strands connected to form a continuous network. Since the network fills space and supports itself, it is considered a solid.

What happens if I touch it?

Silica aerogel is semi-elastic because it returns to its original form if slightly deformed. If further deformed, a dimple will be created. However, if the elastic limit is exceeded, it will shatter catastrophically, like glass.

Is aerogel such a good insulator because the air within is trapped and immobile? And, is this why it doesn't melt?

Heat is transferred in three ways: convection, conduction, and radiation. Aerogel is a good thermal insulator for convective heat transfer because the air is severely limited in the distance that it can move and thus transport heat energy. The pores of a typical 20 mg/cc silica aerogel are roughly 0.00000001 meters in diameter. Aerogel is a good conductive insulator because the silica molecules are not as well "connected" as those in a metal (a good thermal conductor). Silica aerogel is a poor radiative insulator because infrared radiation (which transfers heat) passes right through silica aerogel. For this reason, carbon was added to the MER aerogel to stop infrared radiation from passing through it. This is also why one feels the heat from a flame. Air is a poor convective transporter of heat, but infrared radiation passes right through air, from the flame to your hand.

Note: the index of refraction depends on the density of the aerogel.

Would it be possible to create aerogel lighter than air by using helium instead of air?

Aerogel cannot be made less dense than air by filling it with helium. You might be able to make it less dense than the surrounding atmosphere by filling the aerogel with helium and then placing it in an atmosphere of radon or possibly xenon.

Aerogel

Aerogel is a manufactured material with the lowest bulk density of any known porous solid. It is derived from a gel in which the liquid component of the gel has been replaced with a gas. The result is an extremely low-density solid with several remarkable properties, most notably its effectiveness as a thermal insulator and its extremely low density. It is nicknamed frozen smoke, solid smoke or blue smoke due to its translucent nature and the way light scatters in the material; however, it feels like expanded polystyrene (styrofoam) to the touch.

Proposal

To investigate intrinsic and extrinsic properties of the material, aerogel, in order to conceive a polyvalent smart wall. This study will work in conjunction with the architecture comprehensive studio: RE_SORTBODYMIND.

Smart Material Challenge

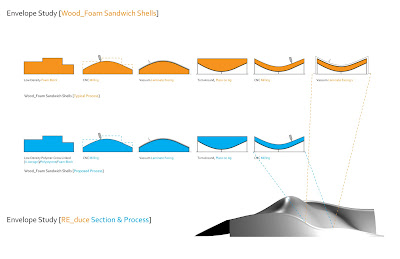

To conceive a polyvalent smart wall as a system of different layers: structure, skin (or envelope), smart material application with possible sensors and actuators.

- 3D performance simulations

- 3D modeling of multi-layered building envelope

- Physical mock-ups/prototypes in appropriate scale

- Physical mock-ups/prototypes in appropriate scale

- Technical drawings of the building components and building systems

Subscribe to:

Posts (Atom)